4. Structures and Mechanisms

Software Lab for Structures

To aid your design of the structures subsystem on paper, we recommend putting together a mass budget and conducting finite element analysis evaluating the stress from the critical load on your primary structure.

Structures – Mass Budget

A mass budget keeps track of how much mass your system is to verify that your design falls below the maximum mass requirement. Here’s the Artemis CubeSat Kit’s Mass Budget Template that you can base your mass budget on.

Structures – Structural Analysis using Finite Element Analysis (FEA)

authored by L. Danielle Young

Learning Objectives

Understanding how to do or retrieve the following information from Finite Element Analysis:

- Mass and Center of Gravity

- Setting Boundary Conditions and Fixtures

- Probing Critical, Structural Load

Purpose

In order to qualify a structure based on requirements (see under the References section of this lab).

Background and Key Concepts to Consider

Application of: General Arrangement and Design Drivers (Mass, Structural Loads, Materials) and Structural Analysis.

Artemis CubeSat Kit description of structures:

- 1U CubeSat frame

- Frames: Aluminum 6061 T6, hard anodized

- Fastener materials

- Rods: 304 Stainless Steel

- Inserts: 18-8 Stainless Steel

- Screws and nuts: 18-8 Stainless Steel (equivalent Onshape’s 300 SS)

- Spacers: Aluminum 6061 (equivalent Onshape’s Al 6061)

Link to Artemis’ GitHub: https://github.com/hsfl/artemis/tree/master/cad-model

Required Materials & Setup

- Computer with a web browser and internet access (required)

- Computer mouse (required)

- Some mechanics in CAD software utilize the scroll button, right/left click, dragging to rotate, etc. that is difficult (but not impossible) to substitute with laptop trackpads.

- Artemis CubeSat Kit GitHub Repository: https://github.com/hsfl/artemis

- Hardware CAD Models: https://github.com/hsfl/artemis/tree/master/hardware/cad-model

- Onshape – Web & Cloud-Based CAD Software

- https://www.onshape.com/en/

- Sign up for free using Education or Public Makers versions

- Onshape Learning Center

- Instructor-led training, self-paced courses, and more

- Onshape Help

- SimScale – Web & Cloud-Based Analysis Software

- https://www.simscale.com/

- Sign up for free on SimScale

- SimScale Platform Introduction

- SimScale Tutorials

- Example Analyses – example results, parameters

- FEA: Pipe Flexibility Analysis

- Thermal (for later): Transient Thermal Analysis of a Printed Circuit Board

- … and more to explore!

- SimScale Help

- Forum: SimScale CAE Forum

- Documentation: SimScale Documentation | Online Simulation Software

- Public Projects: Public Simulation Projects Library

- Using Onshape with SimScale: Using Onshape CAD Tool and Needing FEA or CFD Software?

- CAEplex – Web & Cloud-Based Analysis Software (alternative, not used in tutorials)

- https://www.caeplex.com/

- Sign up for free on CAEplex

- CAEplex Tutorials

Procedure

Additional help links from official software help sites are linked with each step name. These procedures assume you are working on a desktop/laptop computer, not a mobile device.

Preliminary Lab Procedures

1. Downloading the model

- Visit Artemis’ GitHub: https://github.com/hsfl/artemis

- Navigate through the repository following hardware -> cad-model (https://github.com/hsfl/artemis/tree/master/hardware/cad-model)

- Look for the most recent revision of the CAD model (file name appears as Artemis-RX)

- Click on the file name, then the “Download” button to retrieve the .zip file of the structure model.

2. Importing models into Onshape

- See Onshape’s tutorial on importing (link)

- Log onto your Onshape account then select “Import files” under the “Create” button

- Import zip file by selecting the “splitting into multiple documents” option.

- Selecting the option to split into multiple documents will preserve links/references in the assembly file (however, this does not retain mates made from other CAD software).

- Note: importing the assembly onto the OnShape browser may take a few minutes, based on the speed of your internet connection.

3. Defining material properties

With the model imported to your Onshape account, open the .zip file found in the zip folder from your Onshape dashboard.

- Click the part at the bottom of the screen to open the individual part. You can then assign the material to that part.

- Alternatively, you may double-click on the part. It will open a new tab.

- Right-click on the part name found in the left-hand column and select “Assign material”

- A window will pop up and allow you to select a material library and material. By default, the Onshape material library will be selected.

- Select Aluminum 6061 from the drop-down menu under the Onshape material library and click on the check box. Be sure to create a new version of the part by clicking the “Create version” button on the left-hand side of the part name above the toolbar.

The following steps will be summarized to assist in assigning materials for the remaining parts of the structure, as only one part was assigned material in the past few steps.

- Assign the top and bottom sections as Aluminum 6061. As a shortcut, you can double click on the parts in the instances column to open the part with editing enabled. The parts should appear in the context of the assembly where everything but the selected part is transparent. Create and return to the assembly after assigning the material.

- Repeat the previous steps for the rod and screws.

- Screws located on the mid-section part: 300 Series Stainless Steel

- Screws located on the top-section and bottom-section parts: 18-8 Stainless Steel

- Rods: 300 Series Stainless Steel

- Refer to the figure shown below for assistance.

Note: Once you have assigned the materials for the rods and screws, the assembly file will indicate to parts to be updated. Be sure to update the parts in order to get a complete estimation of the structure’s mass.

4. Reorienting the coordinate system and origin

This step is done to orientate the model so that it follows the correct orientation as if placed in a deployer. The structure should be oriented such that the “top” view/face in the modeling software shows the part of the structure with the four protruding corners from the rails (part name: top-section). The “bottom” view/face in the modeling software should show a similar part, with holes going through the protruding feet of the rails of the structure (part name: bottom section). The “front”, “back”, and side (“left” or “right”) views should show the midsections of the structure (part name: mid-section).

If correctly aligned in the modeling software, the structure should appear with the internal rods pointing vertically, up, and down.

- Select the entire assembly by clicking on the “Artemis” assembly list item under the instance column. A coordinate system should appear on your screen, and the entire assembly should be highlighted in yellow.

- On the coordinate system shown hovering over the selected assembly, right-click on the arrow of the axis that you want to realign to the z-axis. Then, select “Align with Z” from the pop-up menu shown.

- The model should reorientate the assembly to the desired coordinate system.

- Ensure the bottom section is oriented towards the bottom. If not, select anti-align instead

Note: You can use the viewing cube on the upper-right-hand side of the screen as your coordinate system. This can be used as a visual reference or directly clicked on to show a desired view of the assembly. For example, clicking on “Top” on the viewing cube will move the assembly so the top face is shown.

The assembly should now show the model with the correct orientation. The origin, indicated by two black rings, should be in the center of the structure’s volume/cube. If the assembly is off-centered from the origin, then the coordinate system can also be reoriented to align with the modeling software’s origin.

- Select the entire assembly by clicking on the “Artemis” assembly list item under the instance column. A coordinate system should appear on your screen, and the entire assembly should be highlighted in yellow.

In the figure shown, the origin is off to the right, outside of the structure assembly. It should be located on the inside of the cubical volume of the structure.

- At the point of the coordinate system, right-click on the circle. Then select “Move to origin”.

- The model should be shifted so the origin and coordinate system are now aligned.

5. Import Onshape files into Simscale

- See Onshape tutorial on Simscale (link)

To run an FEA in SimScale, parts can be imported into Simscale via Onshape to run an analysis. For the FEA analysis, the whole structure will be analyzed.

First, a New Project must be made on Simscale.

From your Simscale dashboard (https://www.simscale.com/dashboard/), create a “New Project” by clicking on the button on the top right.

Give the Project a Title – be sure to make it something helpful and descriptive. A Project Description, Category, and Tags can also optionally be added as desired.

When done, click on the “Create project” button at the bottom of the “New Project” window. Next, after opening the newly created project, an “Import Geometry” window will pop up, prompting to add files for the Simscale project. If no window pops up, look at the “GEOMETRIES” section under the Tree on the left, and click on the “+” plus sign.

From here, files can be uploaded from the user’s computer or Imported from Onshape. For this lab, since Onshape is the modeling software being used, we will import the file from Onshape. Click on the “Import from Onshape” button on the bottom right of the Import Geometry window. If the user has not used Simscale with Onshape before, an authorization window may pop up first.

Then, an Onshape Connector App window will open to allow users to import models from their Onshape account. Import the entire Artemis structure assembly file. Users will have to scroll through to find the correct file from the list generated. If the file isn’t listed from the initial list provided, scroll down and click on the “Load more” button.

After the correct file appears, select it and click on the “Import” button.

After authorizing linking Onshape with SimScale then you can import the file from Onshape, and click on the “Import” button.

Main Lab Procedures

- Simscale provides an in-depth page on how to set up simulations and more external help links here: Simulation Setup in the SimScale Workbench

- Unless otherwise stated, default settings will be used for the simulation properties.

- Key Indicators to note:

Incomplete state

Incomplete state

- Indicated by a red, open circle

- Settings in this state must be configured as a critical part of the simulation

Complete state

Complete state

- Indicated by a green circle with a checkmark

- Settings in this state do not need to be configured unless it is necessary or noted.

Optional state

Optional state

- Indicated by a blue, open circle

- Settings in this state may or may not need to be configured. Again, this tutorial will only detail settings to adjust.

Error state

Error state

- Indicated by a red circle with an X

- Settings in this state have an error and must be reconfigured.

1. Mass and Center of Gravity

See Onshape’s tutorial: Mass and Center of Gravity (link)

- Open the assembly or zip file (model of the entire Artemis structure). Locate the mass properties tool (bottom right-hand corner of the window, the icon appears as scales/balances.)

Icons for the Measurement and Mass properties tools, click to display the window.

- Click on the Mass Properties tool and a pop-up window should appear. Select the assembly file and the mass properties should populate within the window.

Note: If no properties appear, be sure to check that the parts have been assigned a material. The faces are aluminum and the screws/rods are steel.

- Based on the part’s geometry, the CAD software will find the total mass, volume, surface area, center of mass, and moment of inertia calculations. The center of mass will be indicated in the black and white, circular symbol.

Note: If the point of origin for the model is off, refer to the preliminary lab procedures under the section to reorient the Z-axis

2. Define boundary conditions and fixtures

To run the FEA analysis, the entire Artemis structure will be analyzed in Simscale. Defining the boundary conditions and fixtures is the first step in conducting an FEA Analysis. To do this, a Static Analysis will need to be set up in SimScale.

An example simulation in SimScale using the Artemis CubeSat Kit is viewable here: https://www.simscale.com/projects/ldyoung/artemis_assem_fea/

Initial FEA Analysis setup in SimScale

(link above to SimScale website page)

See also: Creating a Static Analysis in SimScale (link)

With the Artemis structure assembly imported and opened in SimScale, select the appropriate assembly geometry under “GEOMETRIES” in the tree. Click on the “Create Simulation” button.

Next, a window will appear showing all the different types of simulations that can be conducted in SimScale.

- For this lab, a Static analysis will be conducted to analyze when a critical load is applied to the structure, as expected from the mechanical requirements for the Artemis CubeSat Kit.

After selecting Static and “Create Simulation”, a new Static Simulation will show under the Simulation tree.

The Static simulation will show various features of the analysis that can be modified. Going through each feature.

Geometry

(link above to SimScale website page)

Refers to the modeled 3d part imported from Onshape.

Contacts

(link above to SimScale website page)

Contacts are required to be fully defined in order to run a simulation. This describes and affects the degrees of freedom in the model and describes how parts are connected relative to other existing parts in the model.

For this tutorial, bonded contacts will be used. More information on other types of contacts is available on the SimScale website.

- “The bonded contact is a type of contact which allows no relative displacement between two connected solid bodies. This type of contact constraint is used to glue together different parts of an assembly.”

- “You can assign faces or sets of faces that should be tied together via the assignment box under Pick Faces. For numerical purposes, you have to choose one of these selections as master and the other one as slave. During the calculation, the degrees of freedom of slave nodes are constrained to the master surface.”

- Master assignments = blue selection

- Slave assignments = pink selection

For the lab module, only Master and Slave assignments will be adjusted, Position Tolerance and Tolerance settings will be left at the default values.

- Connections = Bonded

- Position tolerance = Set value

- Tolerance = 0.001 m

Upon importing the file into Simscale, the software may automatically create Contact points. These should be checked to ensure they are more accurate to what should be simulated, then can be deleted or edited as necessary.

- Auto-generated contacts may appear as four Bonded contacts. These can be deleted altogether, so new contacts can be added in from scratch (right-click on the desired contact and click on “Delete”. Alternatively, clicking on a bond will bring up the settings for the established contact. From here, under the “Master assignment” and “Slave assignment” sections, click on the trash can icon.

Tip: Contacts can be selected in bulk via CTRL + Click and/or SHIFT + Click.

Contacts to establish in the analysis simulation setup:

-

- Repeat as needed for the entire structure model (all six of the connected top, bottom, and side pieces). Consider the relationships and constraints between the parts to ensure contacts are fully defined.

- Structure frames (top/bottom sections, mid-sections) = BONDED

- Inner surfaces of the top/bottom frames to the inner surfaces of the side frames.

- Note: Select all inner surfaces of side frames, including fillet on inner corners of mid sections. You should select a total of 10 surfaces for the side frames.

- Example contacts:

- Screws to structure section faces = BONDED

- Screw faces (master) flush with the surface of structure plate face (slave).

- Repeat for screws on the top/bottom part of the structure and sides as available.

- Rods to the inner circumference of structure = BONDED

- Inner surface/circumference of the structure plate holes (master) with the outer face of internal rods (slave).

Element technology & Model

Element technology can be selected as ‘Standard’ or ‘Reduced Integration’. Use the default setting, with the type as ‘Standard’.

Materials

(link above to SimScale website page)

“This is where the user defines the simulated material, such as the fluid in a CFD simulation or the material of a solid in a structural analysis. The user can use a predefined material that is available in SimScale or use a custom material by changing the physical properties of the material.”

Define the material for the part. The two Artemis structure materials will be assigned as defined in the background section. To assign a material, click on the “+” plus button next to “Materials” in the Simulations tree.

- Aluminum will be assigned to the frame of the structure.

- Stainless Steel will be assigned to the fasteners (screws) and rods of the structure.

- Use the Steel material as the base selection and adjust the material properties to accurately reflect Stainless Steel properties instead.

Assigning Aluminium to the Structure Frames:

For Aluminium, select “Aluminum” from the list and click “Apply”.

From here, Aluminum will be shown as the set material with material properties, and volumes within the model that the property is applied.

Next, select the structure frames as “Volumes” to assign the Aluminum material properties to.

Once all appropriate parts have been selected (highlighted in blue and appearing under the Assignments list), click on the Check button to finish assigning material properties to the desired parts of the structure.

Assigning Stainless Steel to the Structure Fasteners and Rods:

For Stainless Steel, select “Steel” from the list of materials and click on “Apply”.

After it has been selected, the material property values can be adjusted to better accurately reflect the materials used on the Artemis structure (which can also be referred to in the Background section of the lab).

- Stainless Steel properties to adjust:

- (E) Young’s modulus: 193 GPa or 1.93e+9 Pa

- (ρ) Density: 8 km/m3

Next, select all of the fasteners (screws) and rods in the structure as “Volumes” to assign the Stainless Steel material properties to.

Once all appropriate parts have been selected (highlighted in blue and appearing under the Assignments list), click on the Check button to finish assigning material properties to the desired parts of the structure.

Boundary conditions

(link above to SimScale website page)

“Boundary conditions define how a system (for example, a structure or a fluid) interacts with the environment. Fixations, loads, pressures, flow rates, or velocities are all examples of boundary conditions.”

- Fixed Support

- If a fixed support constraint is used, all degrees of freedom of the selected entities are fixed at zero. This constraint is often used to model a fixation to the ground or an undeformable part.

- Assignment – select the bottom faces of the square rails to apply the fixtures.

- Force

- Fx = 0 N, Fz = 0N

- Fy = -1320 N

- Ensure the model is imported and aligned to the appropriate axes/directions/faces! See pre-lab instructions if unsure.

- Assignment – select the top faces of the square rails to apply the force.

Numerics

(link above to SimScale website page)

“The user can configure the equation solver for the simulation, change the convergence settings, and other numerical settings necessary to reach a converged solution. However, it is worth keeping in mind that this is for advanced users only. In most cases, default settings are enough. These are the brains behind running the simulation. Here, you have control over the schemes, solvers, relaxation factors, tolerances, etc that can lead to a successful and efficient solving of a simulation problem. Through these settings, you can control the convergence and stability. It is worth keeping in mind that this is for advanced users only. For most of the cases, default settings are enough.”

These numbers will not be adjusted for this tutorial. Default values are sufficient to use for this tutorial.

- Solver = MUMPS

- Precision singularity detection = 8

- Stop if singular = ON (slider to the right)

- Matrix type = Automatic detection

- Memory percentage for pivoting = 20

- Linear system relative residual = 1 e-5

- Preprocessing = Active

- Distributed matrix storage = ON (slider to the right)

- Memory management = Automatic

Simulation Control

(link above to SimScale website page)

“This is where the user can configure the amount of time the simulation is allowed to run, the number of results that will be saved, and the number of processors that will be used in the simulation.”

Default values can be left the same.

- Pseudo-time-stepping = Single step

- Static time steps = 0 s

- Number of processors = Automatic (up to 16)

- Maximum runtime = 3600 s

Mesh

(link above to SimScale website page)

“This is where the discretization of the model is defined. The user can choose the meshing algorithm and the level of fineness that the mesh needs to achieve. The quality of the mesh heavily influences whether the simulation can be run or if the results are accurate enough. The user can also create multiple meshes for one geometry.”

Note: Changing the mesh fineness can affect the computation time, which determines how the simulation runs.

For the first simulation, the following mesh settings can be used.

- Algorithm = Standard

- Sizing = Automatic

- Fineness = 6 (in between Coarse and Fine)

- 2nd order elements = OFF (slider to the left)

- Number of processors = Automatic

After defining the mesh, you can see the properties as it is computed by the software. For example, you can see how many cells and nodes consist in the mesh.

Note: You need to generate the mesh before running the simulation.

Running the Simulation

Once the simulation setup is complete, the simulation is now ready to run.

Click on the “+” plus sign next to Simulation Runs.

A “New run” window should pop up, showing the “Resource estimation” information such as duration (time), compute resources (core hours), meshing cell count (number). Click on the “Start” button and the software will begin running the simulation and output results when it is done computing. This may take time, and you may receive an email letting you know when the simulation is done computing. Depending on the complexity of the simulation and model, this can take more or less time.

Troubleshooting

If the simulation setup contains errors, a window will pop up before allowing a simulation to run.

When this occurs, a red message should also be displayed advising why the simulation can’t run. For more details and guidance directly from Simscale on how to address the errors, click on the icon in the upper right corner of the red error message to pop out and trace where errors are identified.

For example, if parts in the assembly have not been assigned a material, Simscale advises which pieces of Geometry are of interest, and how to address the issue in the Simulation Setup tree by looking under Analysis > Materials.

Alternatively, click on the text that says “(click to select)” to begin resolving the issues as Simscale identifies them. Simscale will highlight parts in red to indicate specific components.

For example, if parts in the assembly have not been assigned a material, Simscale will show the components of interest highlighted in red.

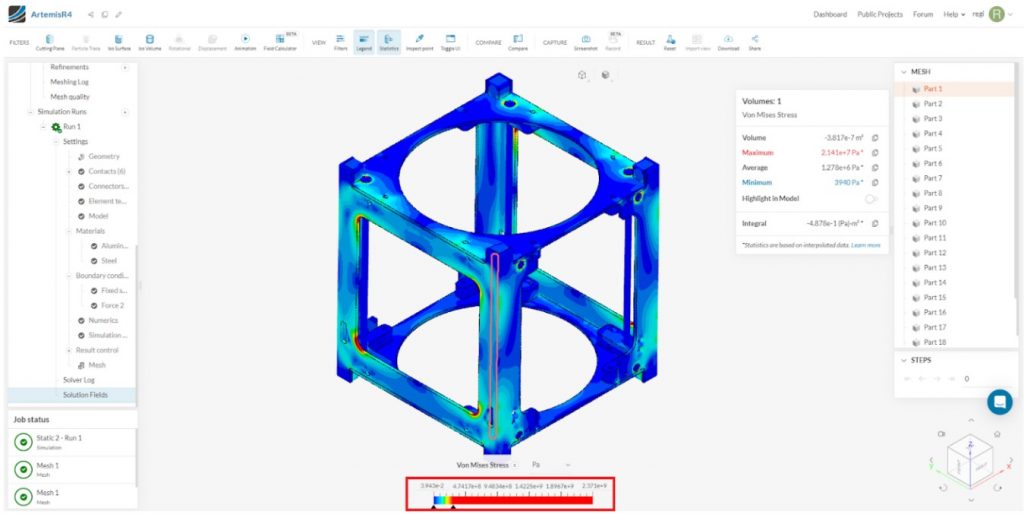

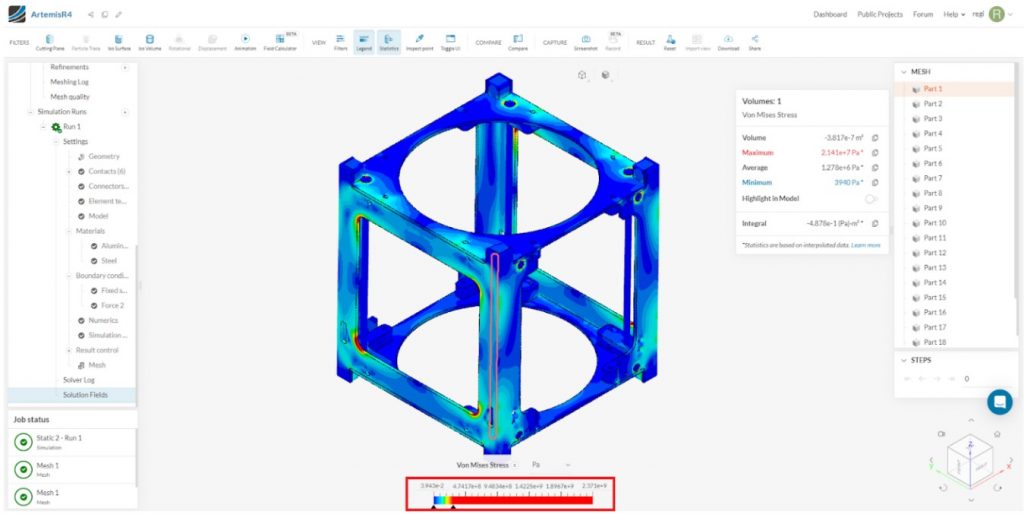

3. Probing Critical, Structural Loads

(link above to SimScale website page)

After the simulation is done computing, you can access the results of the simulation by clicking on the simulation run you are interested in under “Simulation Runs”. Find the simulation run’s results you want to view and click on “Post-process results”.

The model will now show the Von Mises plot (default in Pascals, Pa) on the model. On the scale, red indicates higher points of stress, while blue indicates lower stress.

- Read more on von Mises stress here: What is Von Mises Stress?

Note: The model may look different If the Von Mises Stress scale is adjusted, however values from statistics will stay the same.

Note: The model may look different If the Von Mises Stress scale is adjusted, however values from statistics will stay the same.

To find the von Mises stress at a particular point on the model, right-click anywhere on the model, and select “Inspect point” from the menu. Click on any point to view the specific von Mises stress measured at the node (indicated with the redpoint and smaller window under “Result”).

You may also analyze using statistics tool. These measurements from the simulation results can be used in post-simulation analysis and calculations.

Lab Review and Deliverables

- For EPET/ME 400, view the Structures Analysis Assignment.

- Define critical load for your spacecraft. Back of the envelope calculation of critical load and natural frequencies.

- Finish the finite element analysis structures lab. Solve for the minimum factor of safety. Probe the point of highest stress or lowest factor of safety. Write up intuition to your findings.

- Both tasks will be graded by the Analysis Rubric.

Safety and Best Practices Tips

Onshape

- Onshape Learning Center

- Onshape Help

- Onshape FAQ

- 10 Essential Onshape Tips

- Navigating Onshape for New Users

- Importing Data

- Onshape Self-Paced Course Catalog

- Onshape Videos Course Catalog

SimScale

- SimScale Platform Introduction

- SimScale Knowledge Base and FAQs

- SimScale Engineering Webinars

- SimScale Tutorials

- Example Analyses – example results, parameters

- SimScale CAE Forum

- SimScale Documentation

- Public Simulation Projects Library

- Using Onshape with SimScale: Using Onshape CAD Tool and Needing FEA or CFD Software?

- In the simulation workbench, you can add as many models as you want to the simulation project, allowing you to manage for example design changes and variations. The same models can also be used for distinct aspects, such as stress or thermal analysis.

General CAD tips

- When creating, importing, or dimensioning parts, it is helpful to place the part or assembly relative to the Origin point in the CAD software (as a base point). This allows you to have a reference point in the coordinate space/plane, so future dimensioning or positioning has a constant reference point and can help to prevent errors.

Alternative Activities

Simulation Setup

Several simulations can be set up to test different materials, boundary conditions, loadings, etc.

Consider how these may affect results and be used in the design process.

Additional Result Control

More results are capable of being explored as well using Result Control.

- “If necessary, the user can define additional results to be exported. For example, forces and moments, surface data, and field calculations are some of the additional results that can be exported. The user can also place probe points in the model.”

- Read more on Result Control on the SimScale website.

- Capabilities with Result control:

- Solution fields

- Displacement

- Cauchy stress

- Von mises stress

- Total strain

- Edge calculation

- Area calculation

- Volume calculation

- Point data

- Solution fields

Effects of Structural Supports

- With SimScale and Onshape, options are offered to run multiple simulations and make adjustments to parts.

- Just adjust the thickness of a structural feature or add/remove a part. How does this affect the results? What does this imply about the design?

Vibration Analysis

Frequency Analysis and Harmonic Analysis are also offered in SimScale, which can be used to analyze expected vibrations from launching spacecraft.

References and Other Work

See the Reference Documents section in Chapter 4.6 Structural Analysis for the full list of specifications and requirements.

CubeSat Mechanical Specification from Nanoracks

- The CubeSat shall have four (4) rails along the Z-axis, one per corner of the payload envelope, which allow the payload to slide along the rail interface of the NRCSD as outlined in Figure 4.1.1-1.

- The CubeSat rails and envelope shall adhere to the dimensional specification outlined in Figure 4.1.1-1.

- Each CubeSat rail shall have a minimum width (X and Y faces) of 6mm.

- The edges of the CubeSat rails shall have a radius of 0.5mm +/- 0.1mm.

- The CubeSat +Z rail ends shall be completely bare and have a minimum surface area of 6mm x 6mm.

- The CubeSat rail ends (+/-Z) shall be coplanar with the other rail ends within +/- 0.1mm.

- The CubeSat rail length (Z-axis) shall be the following (+/- 0.1mm):

- 1U rail length: 113.50mm

- 2U rail length: 227.00mm

- 3U rail length: 340.50mm

- 4U rail length: 454.00mm

- 5U rail length: 567.5mm

- 6U rail length: 681 to 740.00mm

- The CubeSat rails shall be continuous. No gaps, holes, fasteners, or any other features may be present along the length of the rails (Z-axis) in regions that contact the NRCSD-E rails.

- The minimum extension of the +/-Z CubeSat rails from the +/-Z CubeSat faces shall be 2mm.

- The CubeSat rails shall be the only mechanical interface to the NRCSD-E in all axes (X, Y, and Z axes).

- The CubeSat rail surfaces that contact the NRCSD-E guide rails shall have a hardness equal to or greater than hard-anodized aluminum (Rockwell C 65-70).

- The CubeSat rails and all load points shall have a surface roughness of less than or equal to 1.6 µm (ISO Grade N7).

Mass and Center of Gravity — Apply in Onshape or Simscale

- The CubeSat mass shall be less than the maximum allowable mass for each respective payload form factor per Table 4.1.2-1.

- The CubeSat center of mass (CM) shall be located within the following range relative to the geometric center of the payload: a. X-axis: (+/- 2cm) b. Y-axis: (+/- 2cm) c. Z-axis: i. 1U: (+/- 2cm) ii. 2U (+/- 4cm) iii. 3U (+/- 6cm) iv. 4U (+/- 8cm) v. 5U (+/- 10cm) vi. 6U (+/- 12cm)

Probing Critical, Structural Loads — Apply in Simscale

- The CubeSat shall be capable of withstanding a force 1320N across all load points equally in the Z direction.

Note: The model may look different If the Von Mises Stress scale is adjusted, however values from statistics will stay the same.

Note: The model may look different If the Von Mises Stress scale is adjusted, however values from statistics will stay the same.